- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

2500-Rock and roll

SNOWBALL

8477.4010.00

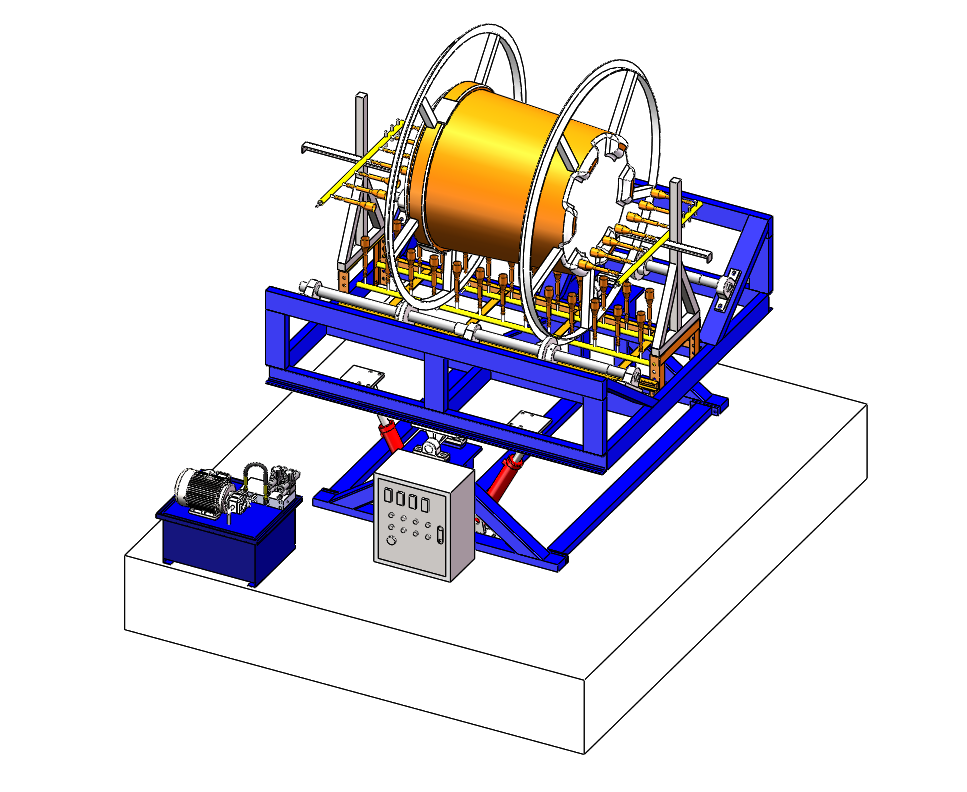

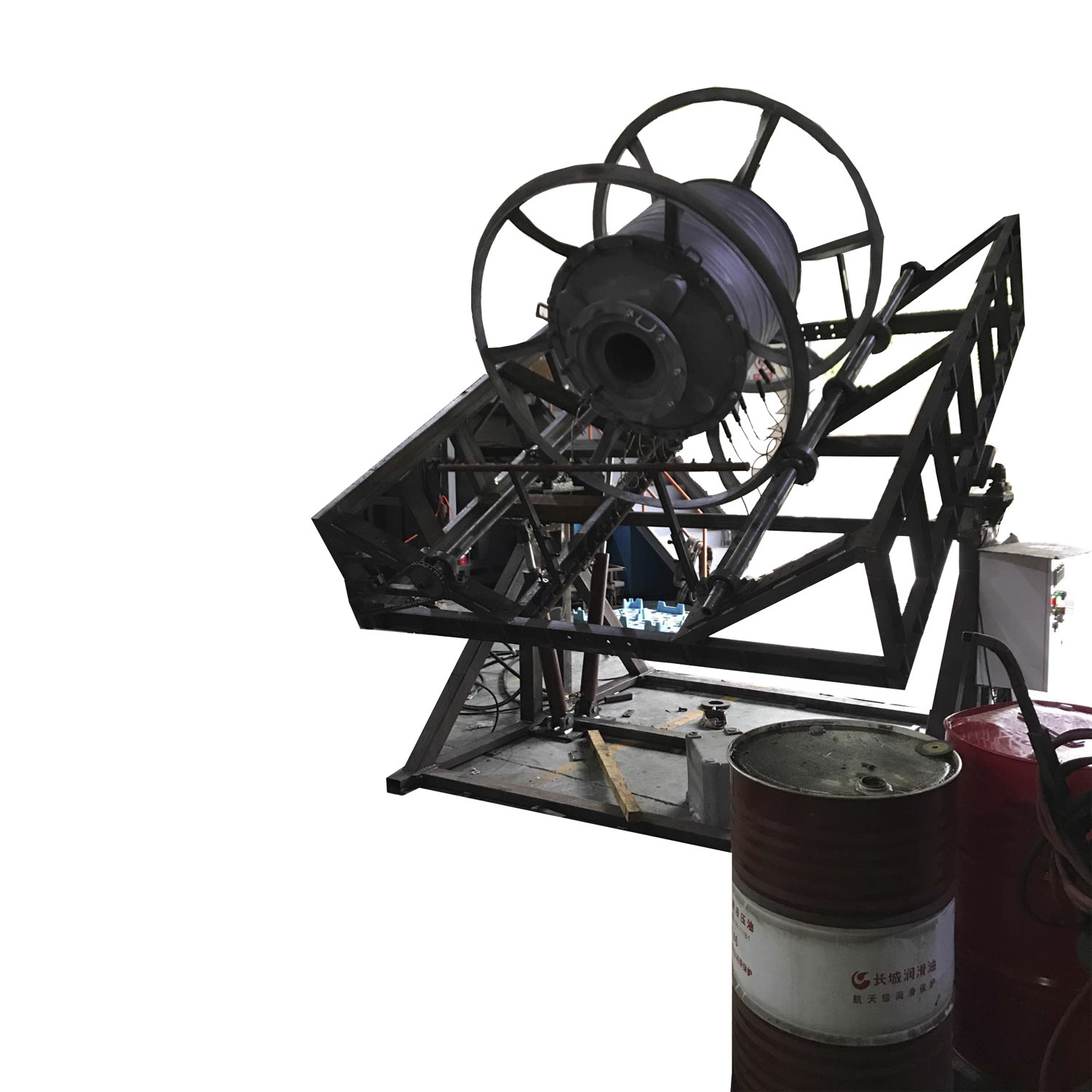

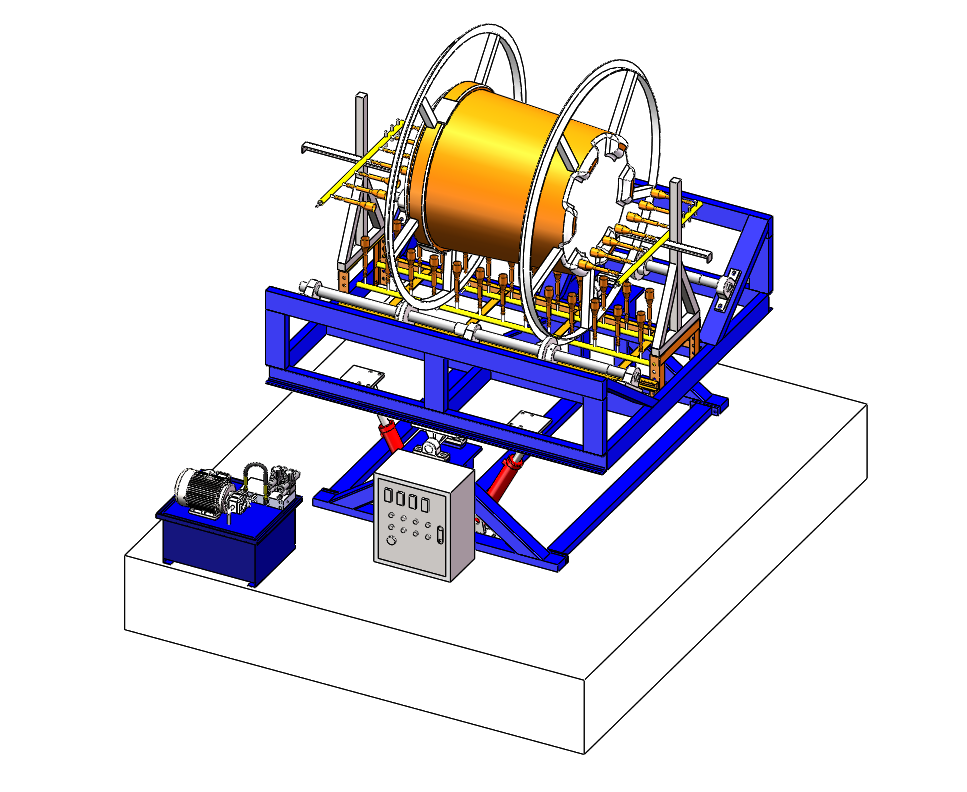

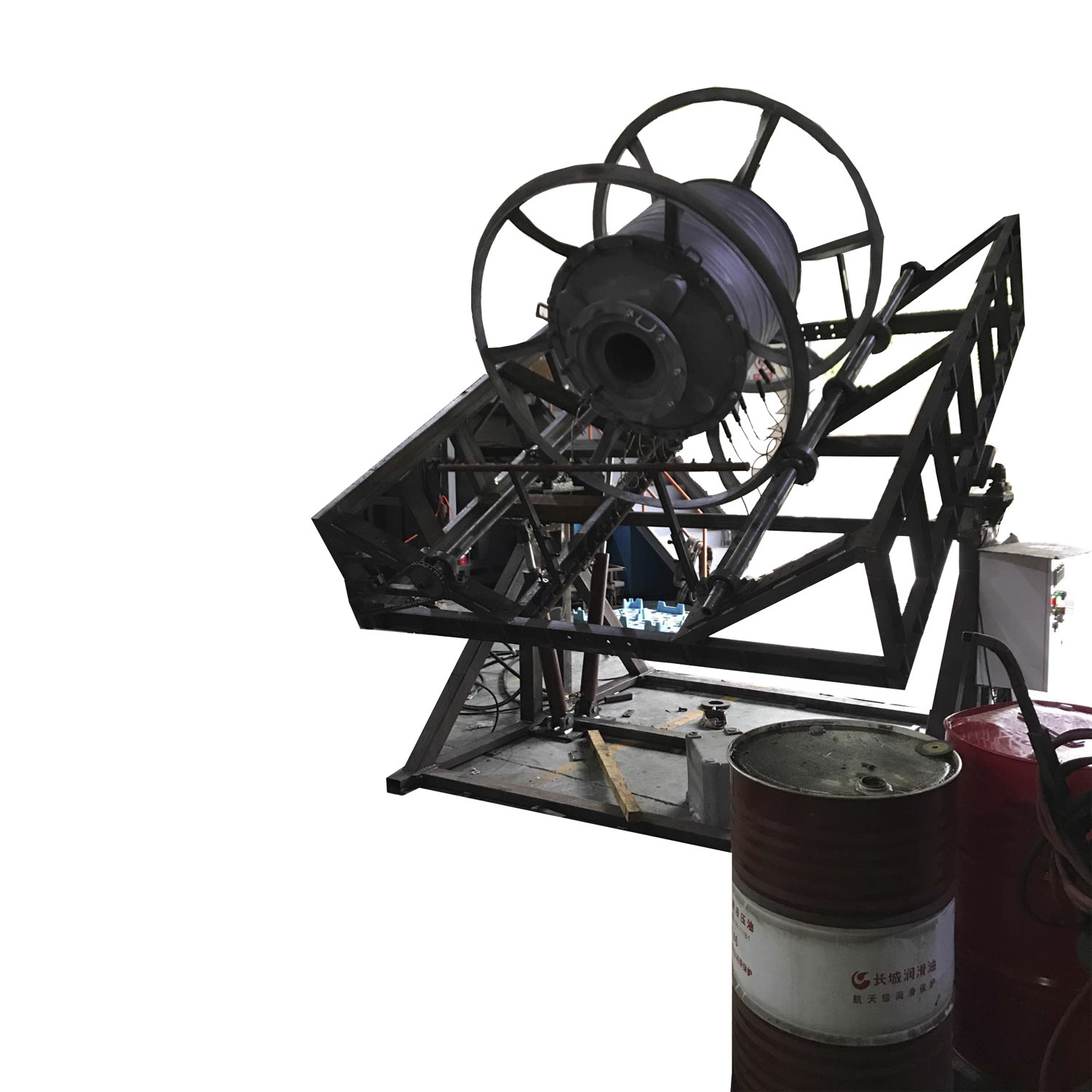

This rock and roll machine is ideal for producing large, elongated molds like kayaks and boats. It offers energy efficiency, ease of use, and can be seamlessly operated via a touchscreen with fully automated controls.

| Parameter | Value |

|---|---|

| Product Name | Open Flame Rock & Roll Oven Rotomoulding Machine for Ferry |

| Brand | SNOWBALL ROTO |

| Origin | China |

| Machinery Type | Rock and Roll Oven Rotomoulding Machine |

| Heating Supply | Natural Gas, Liquefied Gas, Diesel Oil |

| Temperature Control | DTE Control +2°C |

| Burner System | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

| Cooling Mode | Fan Cooling or Water Cooling |

| Control Mode | Touch Screen + PLC (Siemens Brand) |

| Electric Brand | Schneider, Omron |

| Delivery Time | About 60 days after receiving deposit |

| Overseas Installation Period | 10-20 days (depends on machine size) |

| Heating Rate | 3 minutes from room temperature to 280°C in oven |

The Open Flame Rock & Roll Oven Rotomoulding Machine for Ferry by SNOWBALL ROTO, made in China, offers advanced features for efficient and precise molding. Powered by natural gas, liquefied gas, or diesel oil, it uses a high-performance Riello burner system for optimal heating control. With a rapid heating rate of just 3 minutes from room temperature to 280°C, it ensures faster production cycles. The fan or water cooling system accelerates cooling, while the Siemens PLC control system and touch screen make operation seamless. This machine is perfect for creating large, complex molds like kayaks and boats, delivering outstanding energy efficiency and versatility.

Ease of Operation: Simple to use, requires no specialized workshop.

Versatile Heat Source: Compatible with natural gas, liquefied petroleum gas, or diesel.

Energy Efficiency: High-performance insulated oven reduces energy consumption.

Real-Time Monitoring: Monitors oven temperature in real time for consistent product quality.

Recipe Storage: Stores production parameters for efficient process management.

User-Friendly Interface: Multifunctional touchscreen ensures easy operation.

Self-Diagnostic Function: Simplifies maintenance with built-in fault detection.

Remote Diagnostics: Enables troubleshooting from a distance.

Easy Loading/Unloading: Saves time and labor during mold handling.

Automated Control: Fully automated PLC system enhances productivity.

Low Cost: Rotomoulding Machine production costs are 1/3 to 1/4 of blow or injection molding.

Edge Strength: Creates edges with thickness exceeding 5mm for enhanced durability.

Versatile Design: Supports complex shapes and the integration of multiple accessories.

Adjustable Wall Thickness: Easily adjusts wall thickness (2mm and above) without modifying molds.

Hollow, Seamless Products: Ensures structural strength and seamless finishes.

Insulation Capability: Allows foam filling for superior thermal insulation.

Custom Finishes: Offers UV resistance, anti-aging treatments, and a variety of surface patterns.

Wide Color Range: Produces vibrant, high-quality products in various colors.

Welcome to enquiry us! Rotate your business,Snowball your wealth!

This rock and roll machine is ideal for producing large, elongated molds like kayaks and boats. It offers energy efficiency, ease of use, and can be seamlessly operated via a touchscreen with fully automated controls.

| Parameter | Value |

|---|---|

| Product Name | Open Flame Rock & Roll Oven Rotomoulding Machine for Ferry |

| Brand | SNOWBALL ROTO |

| Origin | China |

| Machinery Type | Rock and Roll Oven Rotomoulding Machine |

| Heating Supply | Natural Gas, Liquefied Gas, Diesel Oil |

| Temperature Control | DTE Control +2°C |

| Burner System | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

| Cooling Mode | Fan Cooling or Water Cooling |

| Control Mode | Touch Screen + PLC (Siemens Brand) |

| Electric Brand | Schneider, Omron |

| Delivery Time | About 60 days after receiving deposit |

| Overseas Installation Period | 10-20 days (depends on machine size) |

| Heating Rate | 3 minutes from room temperature to 280°C in oven |

The Open Flame Rock & Roll Oven Rotomoulding Machine for Ferry by SNOWBALL ROTO, made in China, offers advanced features for efficient and precise molding. Powered by natural gas, liquefied gas, or diesel oil, it uses a high-performance Riello burner system for optimal heating control. With a rapid heating rate of just 3 minutes from room temperature to 280°C, it ensures faster production cycles. The fan or water cooling system accelerates cooling, while the Siemens PLC control system and touch screen make operation seamless. This machine is perfect for creating large, complex molds like kayaks and boats, delivering outstanding energy efficiency and versatility.

Ease of Operation: Simple to use, requires no specialized workshop.

Versatile Heat Source: Compatible with natural gas, liquefied petroleum gas, or diesel.

Energy Efficiency: High-performance insulated oven reduces energy consumption.

Real-Time Monitoring: Monitors oven temperature in real time for consistent product quality.

Recipe Storage: Stores production parameters for efficient process management.

User-Friendly Interface: Multifunctional touchscreen ensures easy operation.

Self-Diagnostic Function: Simplifies maintenance with built-in fault detection.

Remote Diagnostics: Enables troubleshooting from a distance.

Easy Loading/Unloading: Saves time and labor during mold handling.

Automated Control: Fully automated PLC system enhances productivity.

Low Cost: Rotomoulding Machine production costs are 1/3 to 1/4 of blow or injection molding.

Edge Strength: Creates edges with thickness exceeding 5mm for enhanced durability.

Versatile Design: Supports complex shapes and the integration of multiple accessories.

Adjustable Wall Thickness: Easily adjusts wall thickness (2mm and above) without modifying molds.

Hollow, Seamless Products: Ensures structural strength and seamless finishes.

Insulation Capability: Allows foam filling for superior thermal insulation.

Custom Finishes: Offers UV resistance, anti-aging treatments, and a variety of surface patterns.

Wide Color Range: Produces vibrant, high-quality products in various colors.

Welcome to enquiry us! Rotate your business,Snowball your wealth!