- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-4000TL

SNOWBALL

8477.4010.00

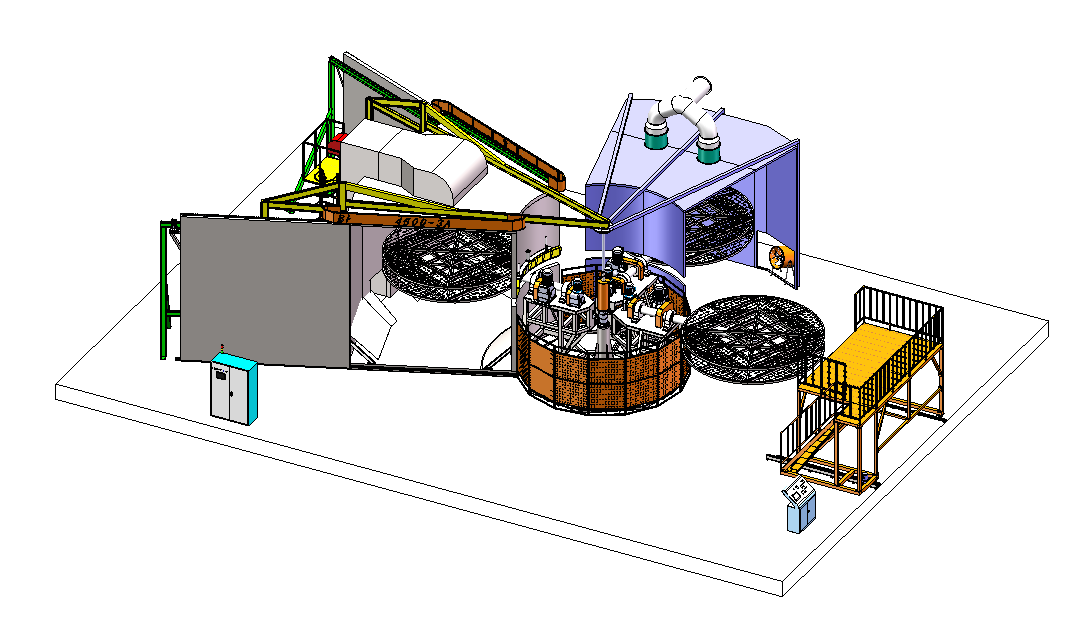

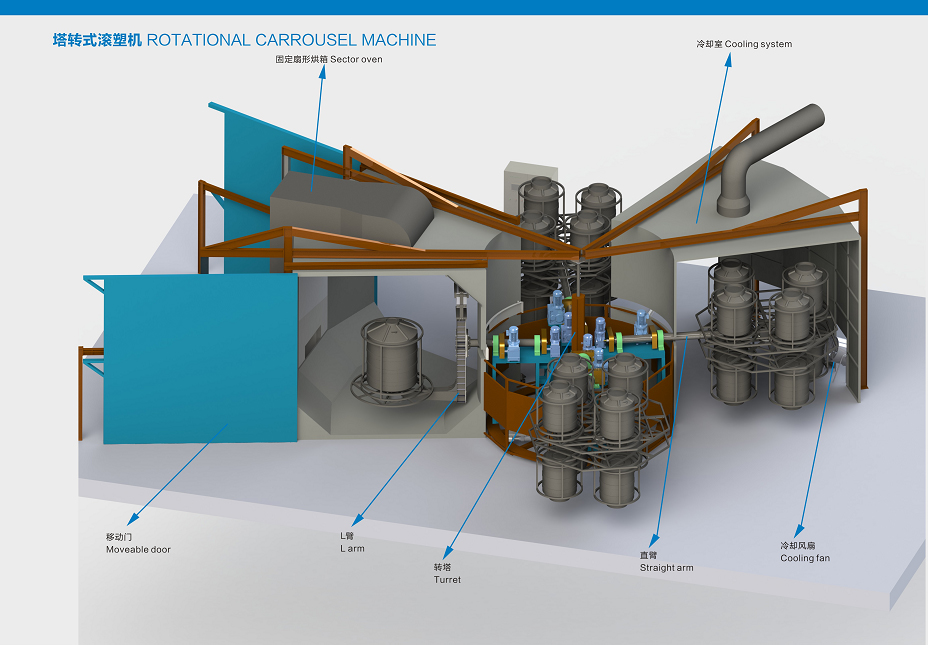

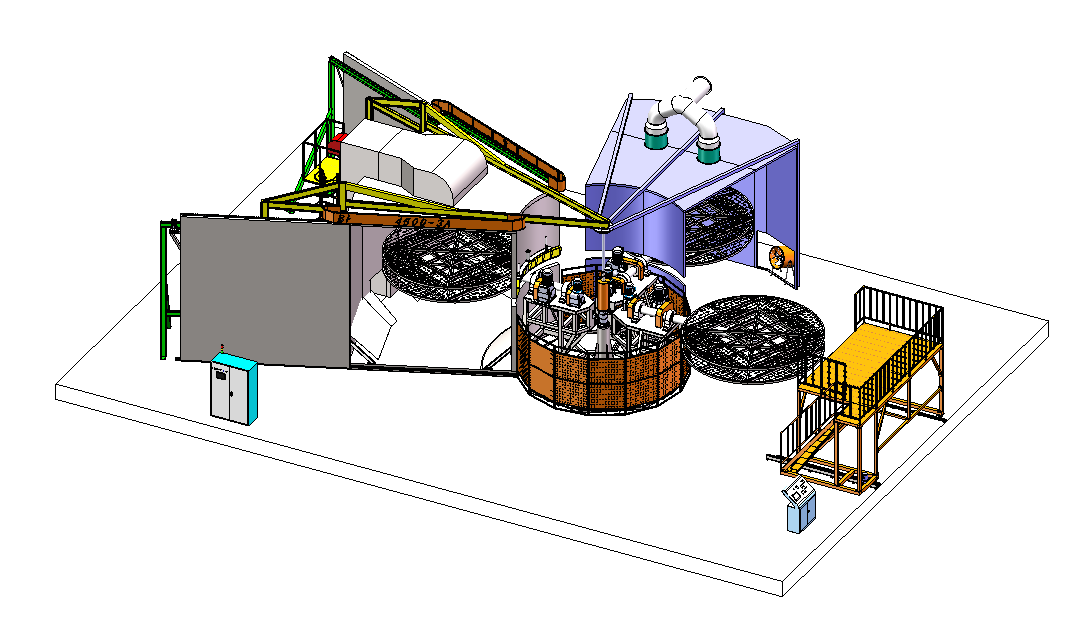

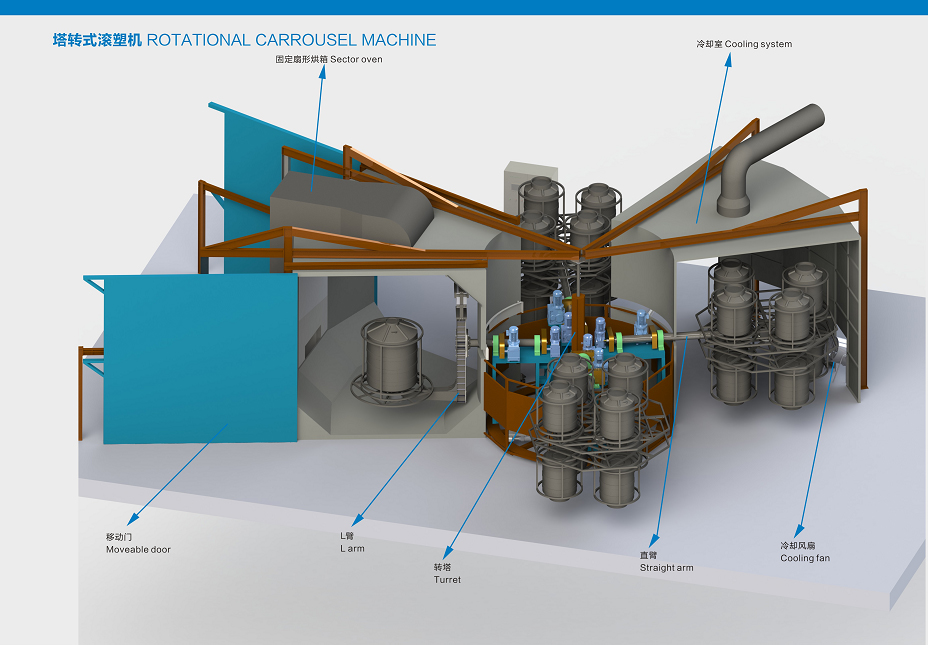

The carousel device is ideal for producing variously sized but similarly shaped large items. It can support either three or four arms and contains three to four stations for heating, cooling, and loading. The contraption features twin doors and the oven is securely attached to the ground.

Technical data sheet:

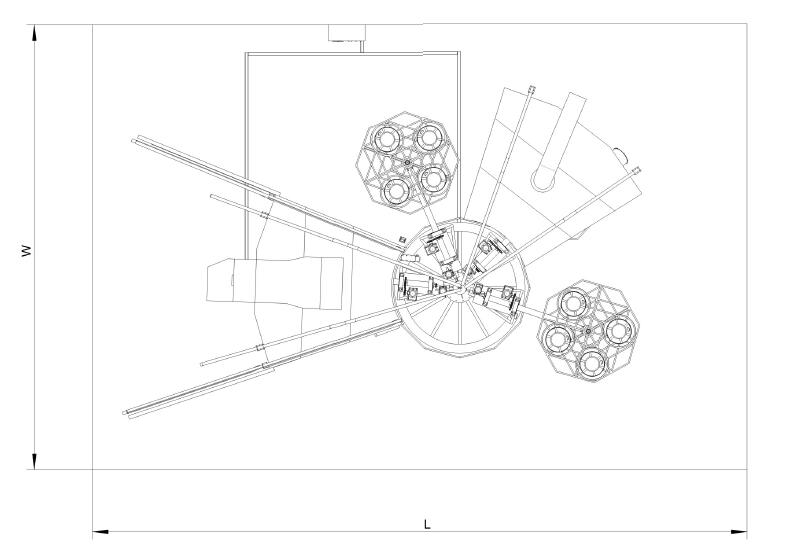

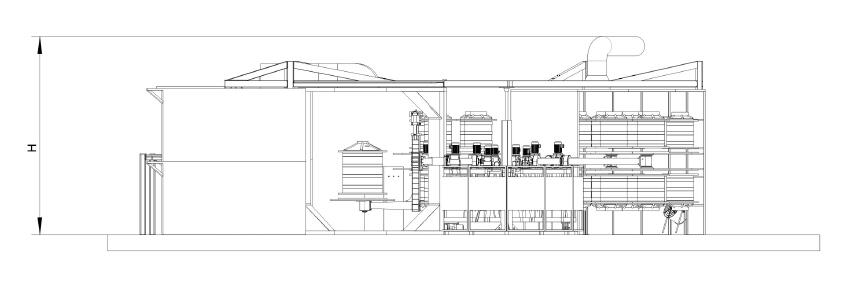

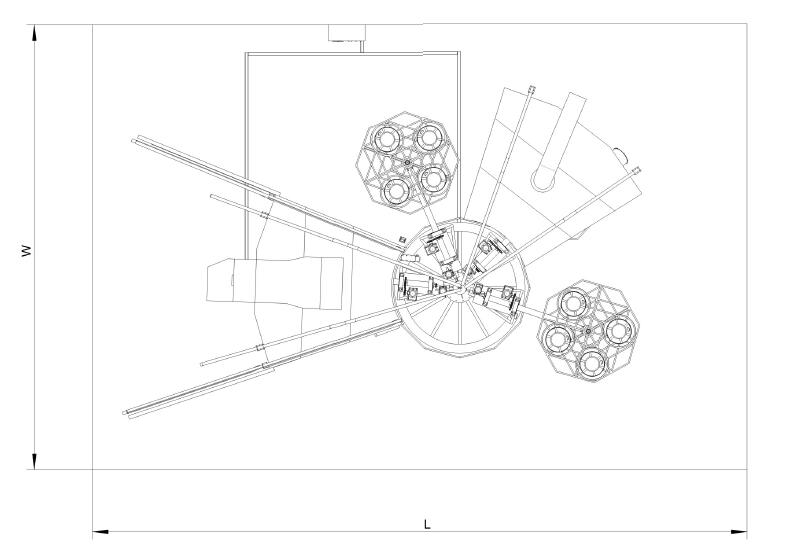

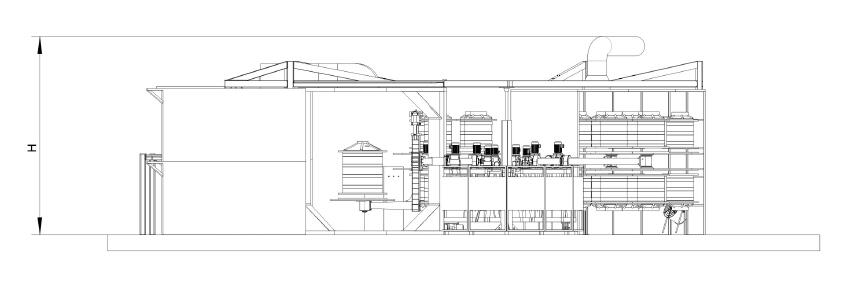

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Machine Premium Features:

Space-saving: Our shuttle-type rolling plastic machine is designed to be very compact, and can be installed in any corner of your factory.

Energy-saving: Our machine adopts advanced energy-saving technology, reducing energy consumption to the lowest.

Safe and reliable: Our machine adopts multiple safety protection mechanisms to ensure the safety of operators.

Finally, we provide comprehensive after-sales services, including installation, debugging, maintenance, and training, ensuring your satisfaction and production efficiency.

Proper maintenance of a rotomolding machine is essential to ensure its optimal performance, longevity, and safety. Here are some general guidelines for maintaining a rotomolding machine:

1. Regular Cleaning: Clean the machine regularly to remove any residue or buildup of plastic material. This includes cleaning the oven, molds, cooling system, and other components. Use appropriate cleaning agents and tools recommended by the machine manufacturer.

2. Lubrication: Lubricate moving parts and bearings as per the manufacturer's recommendations. This helps reduce friction, prevent wear and tear, and ensure smooth operation. Use lubricants suitable for the specific machine components.

3. Inspection and Replacement of Wear Parts: Regularly inspect the machine for any signs of wear or damage, such as worn-out seals, gaskets, or heating elements. Replace these parts as necessary to maintain optimal performance and prevent potential issues.

4. Calibration and Adjustment: Periodically calibrate and adjust the machine settings to ensure accurate temperature control, rotation speed, and other parameters. Follow the manufacturer's guidelines for calibration procedures and frequency.

5. Heating System Maintenance: Clean the heating elements and check for any damage or malfunction. Ensure that the heating system is functioning properly and efficiently. Replace faulty or worn-out heating elements promptly.

6. Cooling System Maintenance: Clean the cooling system regularly to remove any debris or blockages that may hinder proper cooling. Check for leaks or damage in the cooling pipes or components. Repair or replace any faulty parts.

7. Electrical System Inspection: Regularly inspect the electrical system, including wiring, connections, and control panels. Ensure that all electrical components are in good condition and properly grounded. Address any electrical issues promptly to avoid safety hazards.

8. Operator Training and Safety: Provide proper training to machine operators on safe operation and maintenance procedures. Emphasize the importance of following manufacturer guidelines, safety protocols, and best practices. Regularly review and reinforce safety measures.

9. Documentation and Record-Keeping: Maintain a record of maintenance activities, including cleaning, inspections, repairs, and replacements. This helps track the machine's maintenance history and facilitates timely servicing and troubleshooting.

10. Manufacturer's Recommendations: Follow the specific maintenance guidelines provided by the machine manufacturer. These guidelines may include recommended maintenance schedules, specific procedures, and recommended spare parts.

It is important to note that maintenance requirements may vary depending on the specific rotomolding machine model and manufacturer. Always refer to the machine's user manual and consult with the manufacturer or authorized service providers for detailed maintenance instructions and support.

Welcome to enquiry us! Rotate your business,Snowball your wealth!

The carousel device is ideal for producing variously sized but similarly shaped large items. It can support either three or four arms and contains three to four stations for heating, cooling, and loading. The contraption features twin doors and the oven is securely attached to the ground.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Machine Premium Features:

Space-saving: Our shuttle-type rolling plastic machine is designed to be very compact, and can be installed in any corner of your factory.

Energy-saving: Our machine adopts advanced energy-saving technology, reducing energy consumption to the lowest.

Safe and reliable: Our machine adopts multiple safety protection mechanisms to ensure the safety of operators.

Finally, we provide comprehensive after-sales services, including installation, debugging, maintenance, and training, ensuring your satisfaction and production efficiency.

Proper maintenance of a rotomolding machine is essential to ensure its optimal performance, longevity, and safety. Here are some general guidelines for maintaining a rotomolding machine:

1. Regular Cleaning: Clean the machine regularly to remove any residue or buildup of plastic material. This includes cleaning the oven, molds, cooling system, and other components. Use appropriate cleaning agents and tools recommended by the machine manufacturer.

2. Lubrication: Lubricate moving parts and bearings as per the manufacturer's recommendations. This helps reduce friction, prevent wear and tear, and ensure smooth operation. Use lubricants suitable for the specific machine components.

3. Inspection and Replacement of Wear Parts: Regularly inspect the machine for any signs of wear or damage, such as worn-out seals, gaskets, or heating elements. Replace these parts as necessary to maintain optimal performance and prevent potential issues.

4. Calibration and Adjustment: Periodically calibrate and adjust the machine settings to ensure accurate temperature control, rotation speed, and other parameters. Follow the manufacturer's guidelines for calibration procedures and frequency.

5. Heating System Maintenance: Clean the heating elements and check for any damage or malfunction. Ensure that the heating system is functioning properly and efficiently. Replace faulty or worn-out heating elements promptly.

6. Cooling System Maintenance: Clean the cooling system regularly to remove any debris or blockages that may hinder proper cooling. Check for leaks or damage in the cooling pipes or components. Repair or replace any faulty parts.

7. Electrical System Inspection: Regularly inspect the electrical system, including wiring, connections, and control panels. Ensure that all electrical components are in good condition and properly grounded. Address any electrical issues promptly to avoid safety hazards.

8. Operator Training and Safety: Provide proper training to machine operators on safe operation and maintenance procedures. Emphasize the importance of following manufacturer guidelines, safety protocols, and best practices. Regularly review and reinforce safety measures.

9. Documentation and Record-Keeping: Maintain a record of maintenance activities, including cleaning, inspections, repairs, and replacements. This helps track the machine's maintenance history and facilitates timely servicing and troubleshooting.

10. Manufacturer's Recommendations: Follow the specific maintenance guidelines provided by the machine manufacturer. These guidelines may include recommended maintenance schedules, specific procedures, and recommended spare parts.

It is important to note that maintenance requirements may vary depending on the specific rotomolding machine model and manufacturer. Always refer to the machine's user manual and consult with the manufacturer or authorized service providers for detailed maintenance instructions and support.

Welcome to enquiry us! Rotate your business,Snowball your wealth!