- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-4000TL

SNOWBALL

8477.4010.00

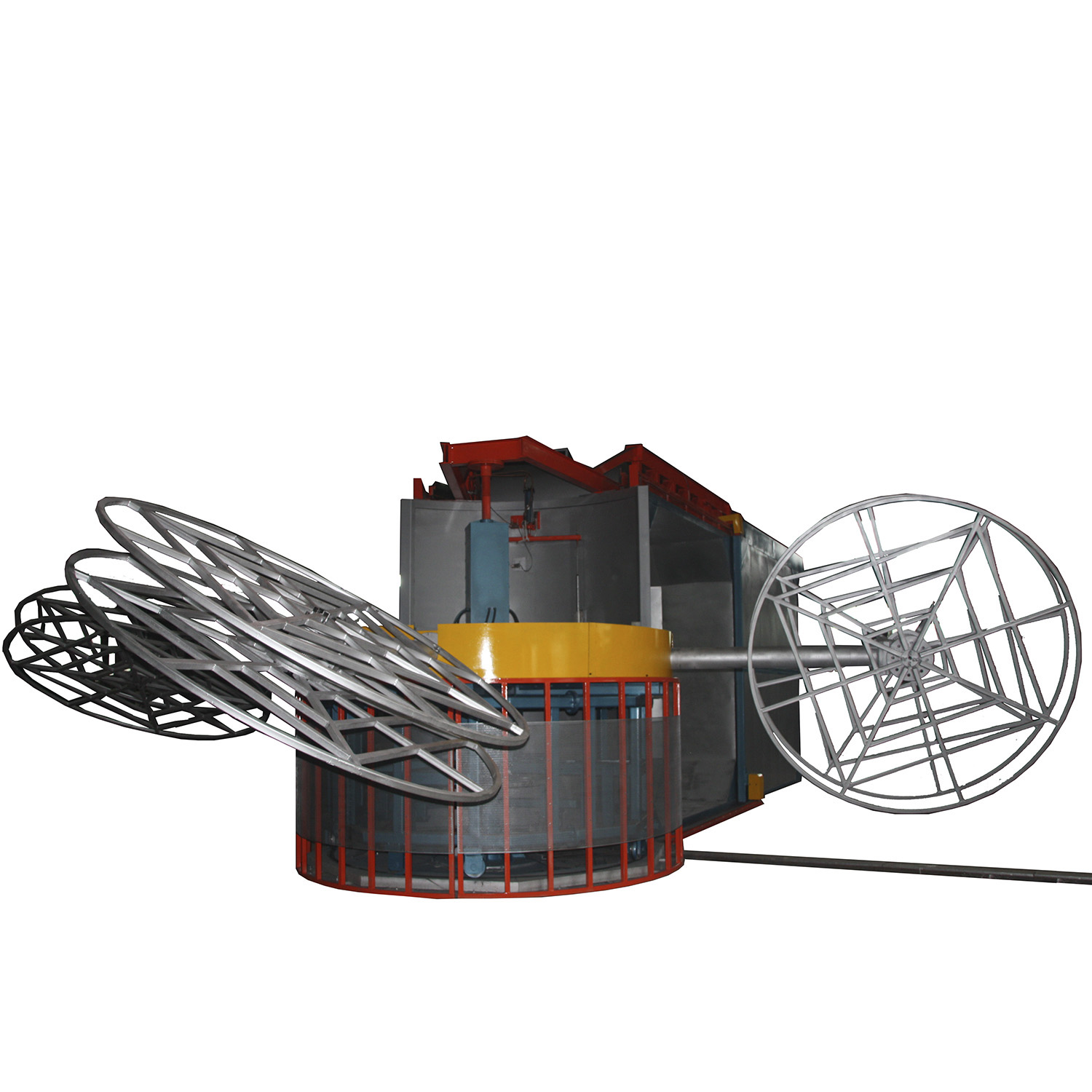

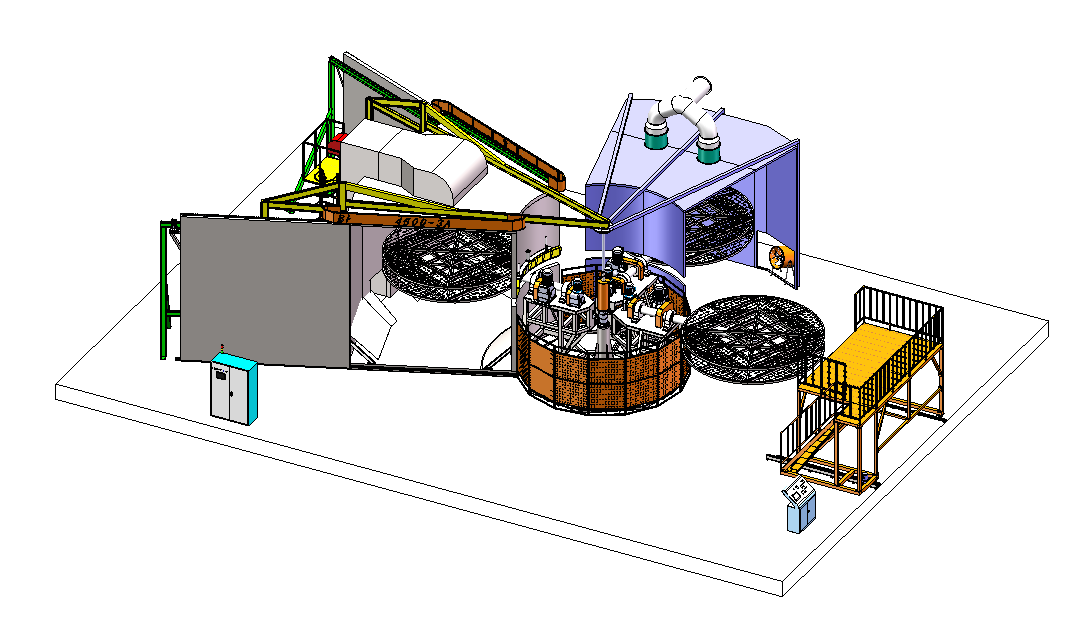

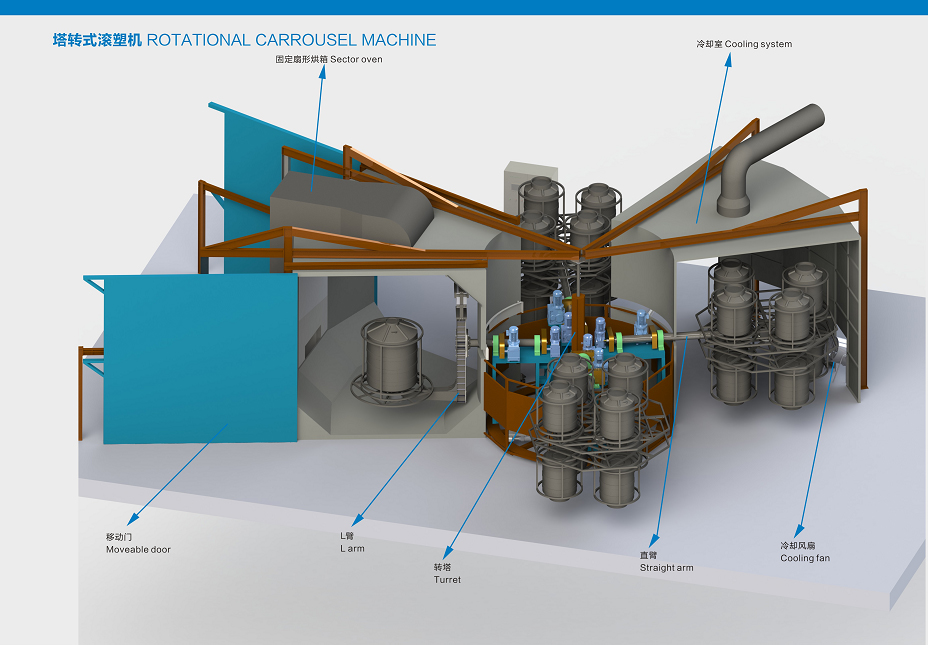

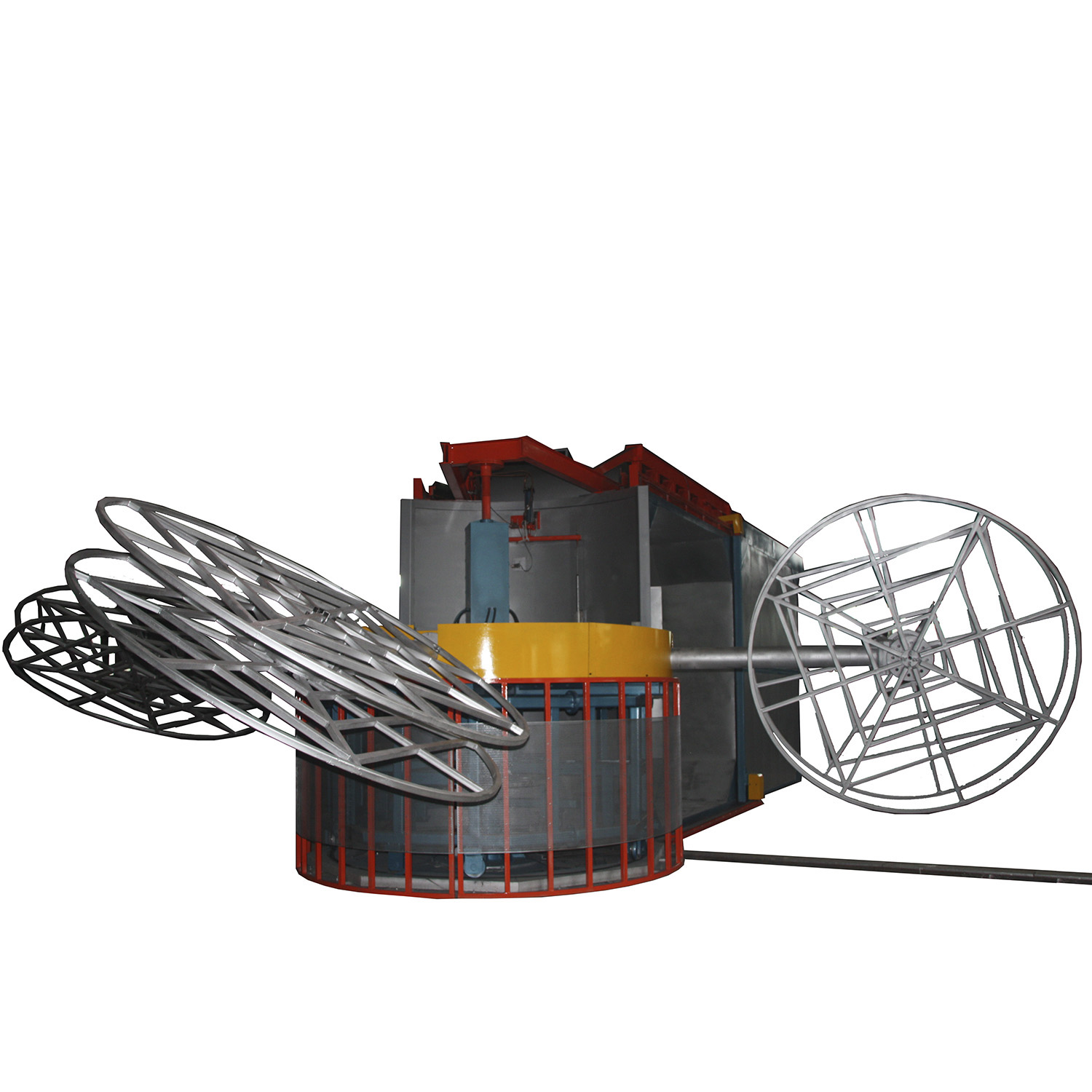

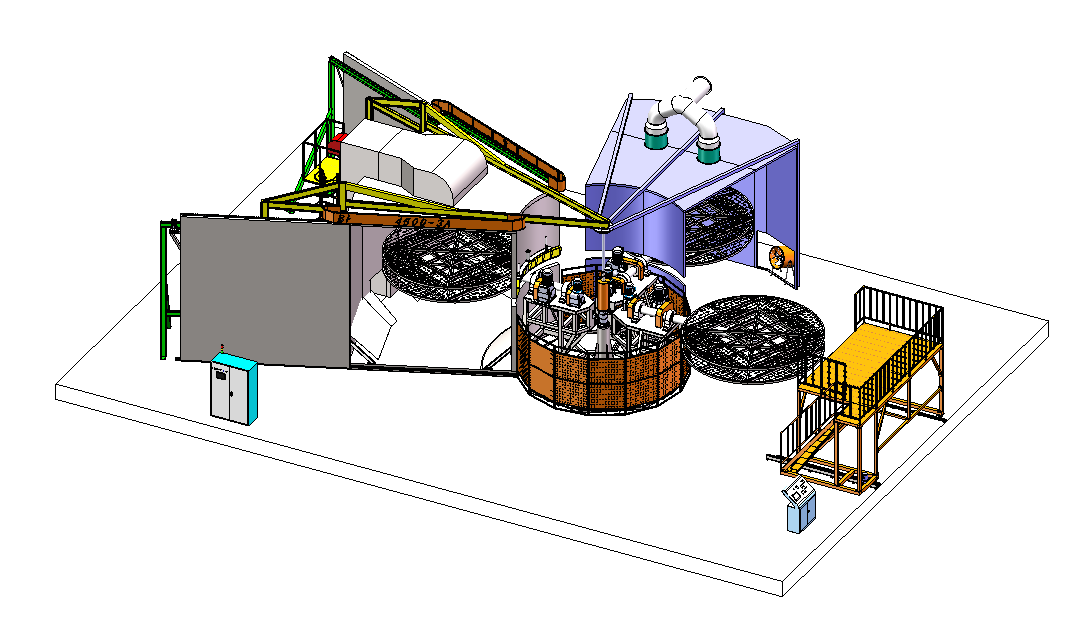

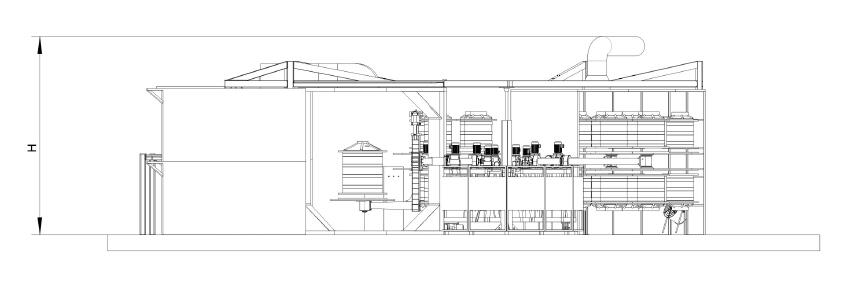

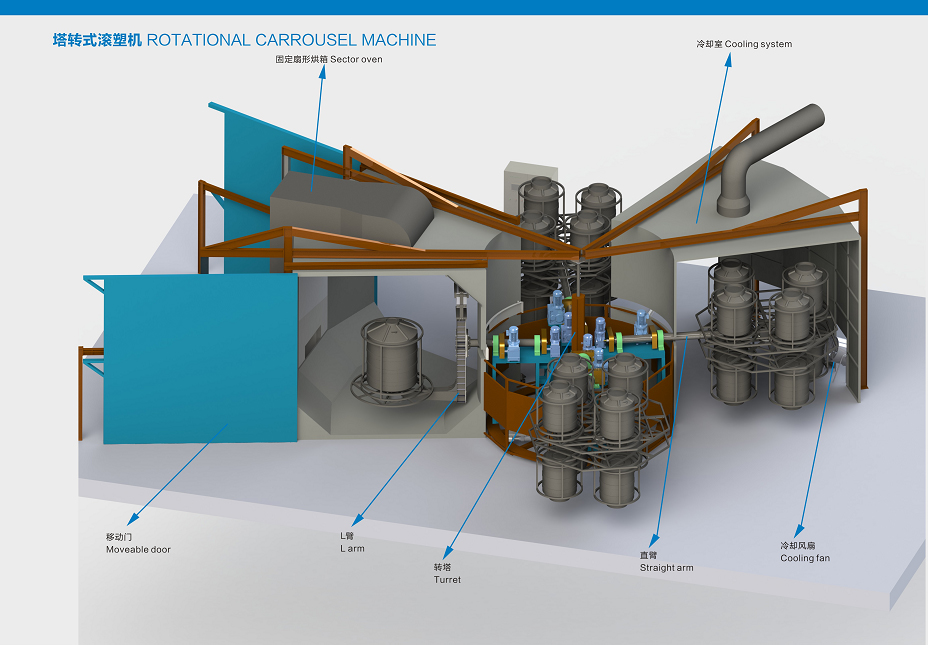

Carrousel rotational molding machine, its central tower bears the weight and the multi beams rotate synchronously. Its main characteristic is that it has relatively high reliability and practicability with simple and fast structure. It is good for producing relatively large products with different sizes but same of similar output frequency. It can bear three to four beams and three to four stations(heating, precooling, cooling and loading)

With the option of having 3 (three) or 4 (four) arms, the Carrousel Serie is a very efficient machine in the manufacturing sequential parts in large quantities, with its 5 stations each step of the process is performed in a specific area, thus minimizing the machine downtime.

With independent stations, the operator can carry out the services of loading and unloading even as the other arms are in the oven time, cooling, or in any other station.

Technical data sheet:

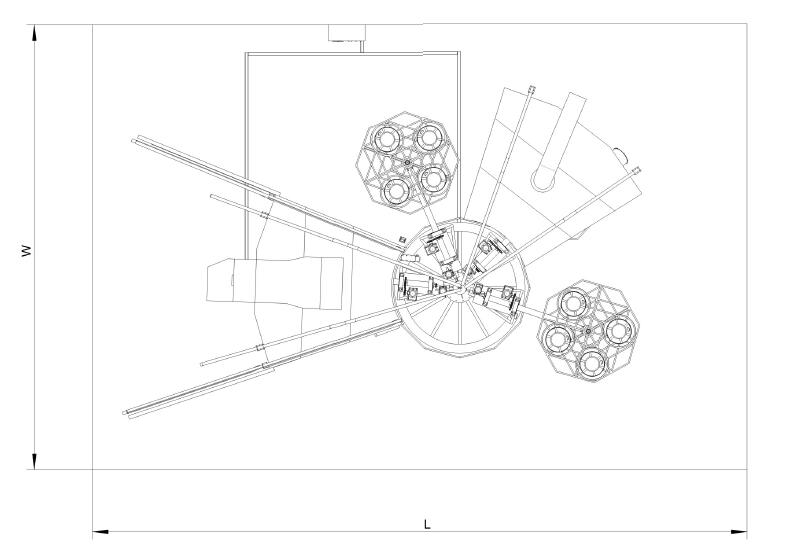

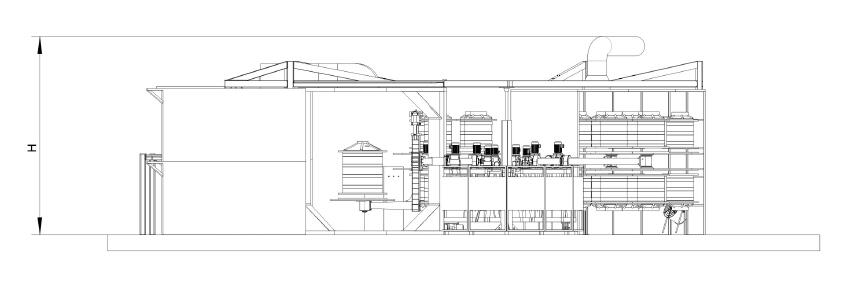

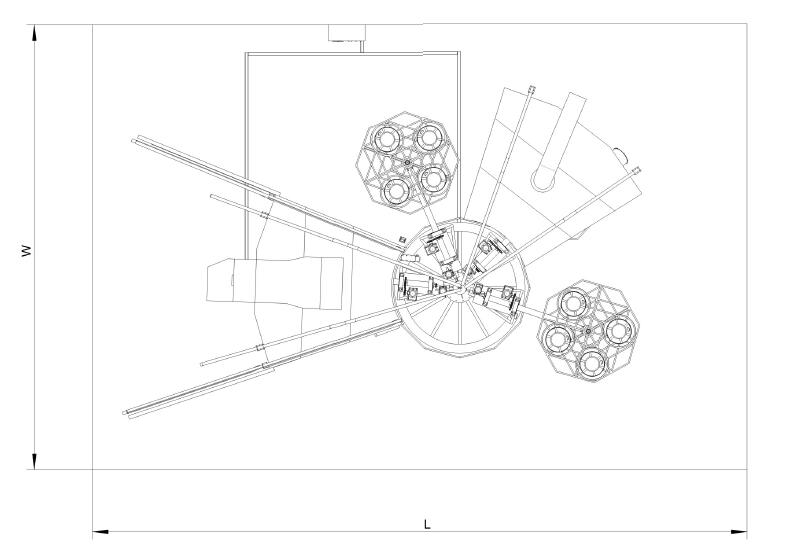

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Our rotational molding machine is of below feature:

1. Sector over. Gear track door fully closed, which is not only transmit more stable and reliable, running safely, free of deformation, but also keep heat from leaking out, reduced power consumption.

2. new type heat circulation system, (double drying tunnel for above 4.5M), increase heat flow volume, make mold heated uniformly, and reduce formation cycle a lot, then production efficiency get improved.

3.Our rotational molding machine is fully automatic controlled with PLC, inverter, touch screen, thermostat, encoder etc., made change from traditional production which is manual control, and heavy labor intensity. Meanwhile, our rotational molding machine could set mold stop at any angle, which makes mold unloading easier and work efficiency improved.

4. Burner is equipped with foreign advanced adjust-comparison system, the mold keep temperature stable, and of less fluctuation.

5. deep cavity heat system, while dealing irregular work piece, and product of uneven thickness at deep cavity and flat corner, it take use heat inside dryer to get compensation and balance heat, and make product more superior.

Carrousel rotational molding machine, its central tower bears the weight and the multi beams rotate synchronously. Its main characteristic is that it has relatively high reliability and practicability with simple and fast structure. It is good for producing relatively large products with different sizes but same of similar output frequency. It can bear three to four beams and three to four stations(heating, precooling, cooling and loading)

With the option of having 3 (three) or 4 (four) arms, the Carrousel Serie is a very efficient machine in the manufacturing sequential parts in large quantities, with its 5 stations each step of the process is performed in a specific area, thus minimizing the machine downtime.

With independent stations, the operator can carry out the services of loading and unloading even as the other arms are in the oven time, cooling, or in any other station.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Our rotational molding machine is of below feature:

1. Sector over. Gear track door fully closed, which is not only transmit more stable and reliable, running safely, free of deformation, but also keep heat from leaking out, reduced power consumption.

2. new type heat circulation system, (double drying tunnel for above 4.5M), increase heat flow volume, make mold heated uniformly, and reduce formation cycle a lot, then production efficiency get improved.

3.Our rotational molding machine is fully automatic controlled with PLC, inverter, touch screen, thermostat, encoder etc., made change from traditional production which is manual control, and heavy labor intensity. Meanwhile, our rotational molding machine could set mold stop at any angle, which makes mold unloading easier and work efficiency improved.

4. Burner is equipped with foreign advanced adjust-comparison system, the mold keep temperature stable, and of less fluctuation.

5. deep cavity heat system, while dealing irregular work piece, and product of uneven thickness at deep cavity and flat corner, it take use heat inside dryer to get compensation and balance heat, and make product more superior.