- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

.

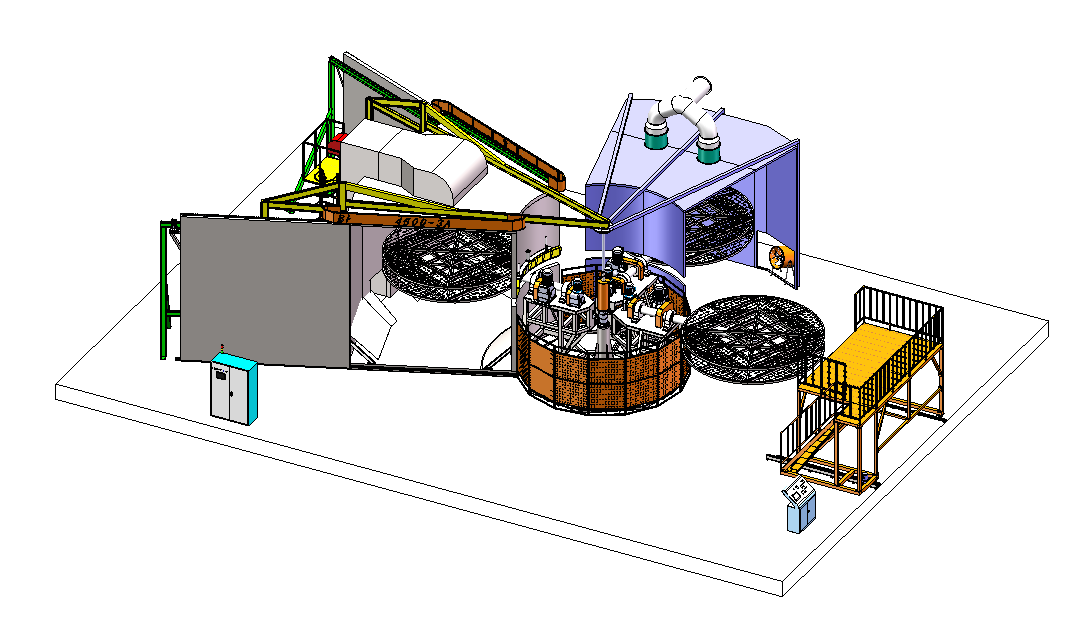

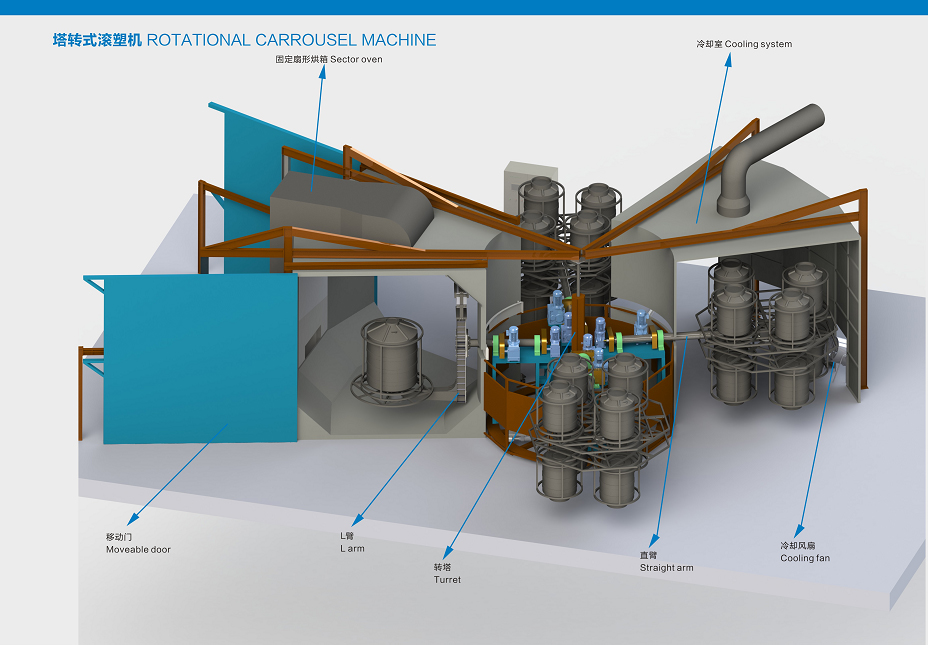

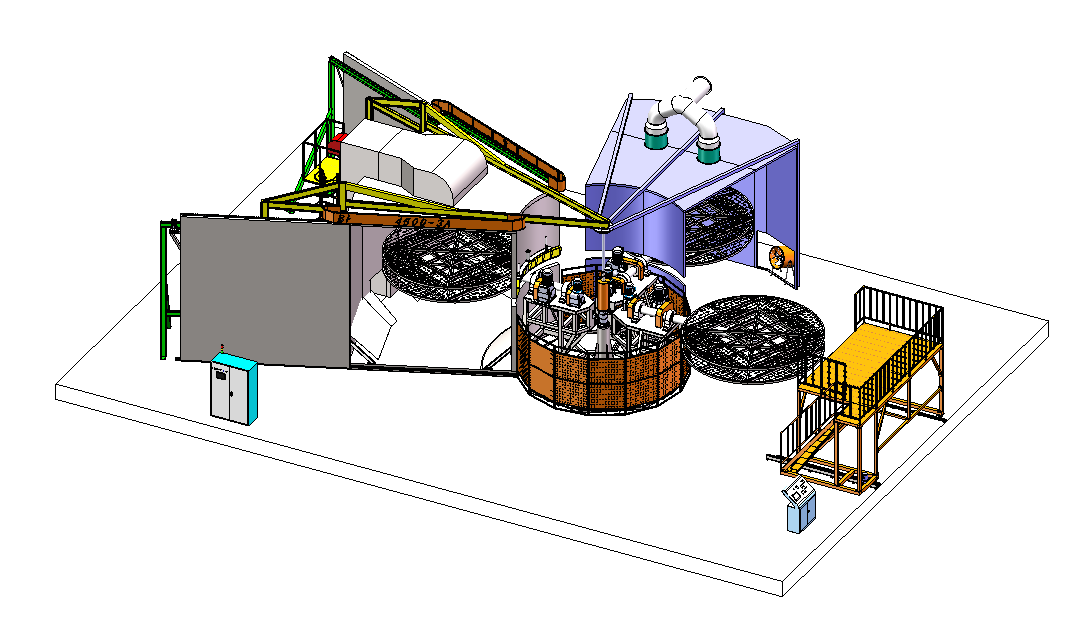

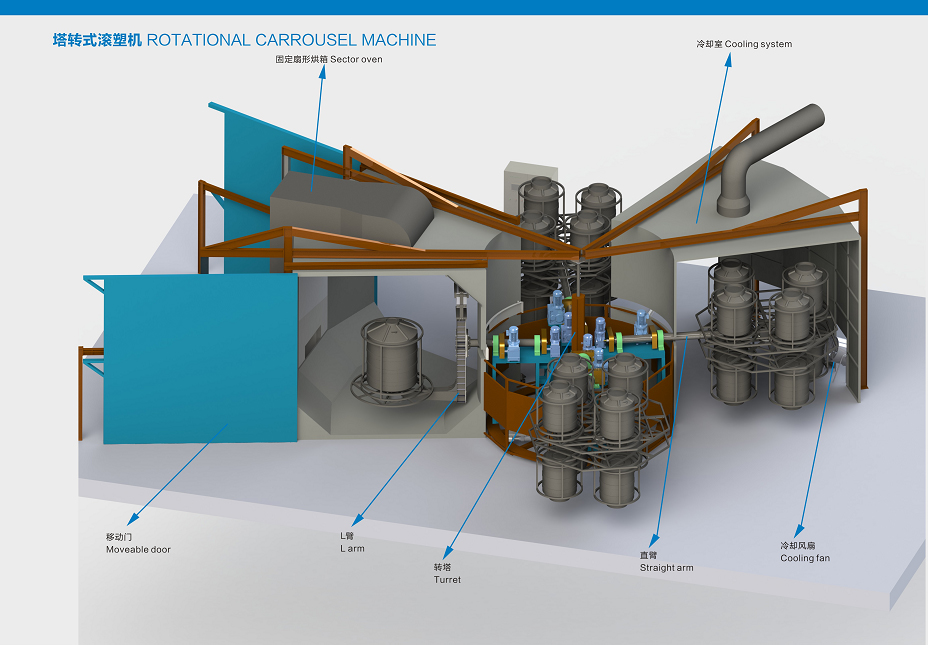

Mold: Rotomolding machines employ molds, typically made of aluminum or steel, to define the shape and dimensions of the final product. These molds are hollow and can be single-piece or multi-piece, depending on the complexity of the desired part.

Oven: The oven is a crucial component of the rotomolding machine responsible for heating the mold and the polymer resin inside it. The oven's temperature and heating profile are carefully controlled to ensure uniform melting and distribution of the resin.

Rotating Mechanism: Rotomolding machines feature a rotational mechanism that rotates the mold along multiple axes simultaneously. This rotation ensures that the molten resin coats the inner surfaces of the mold evenly, forming a seamless, hollow part.

Cooling System: After the rotational molding process is complete, the mold is cooled to solidify the plastic part. Rotomolding machines are equipped with cooling systems, such as fans or water sprays, to expedite the cooling process and optimize cycle times.

Technical data sheet:

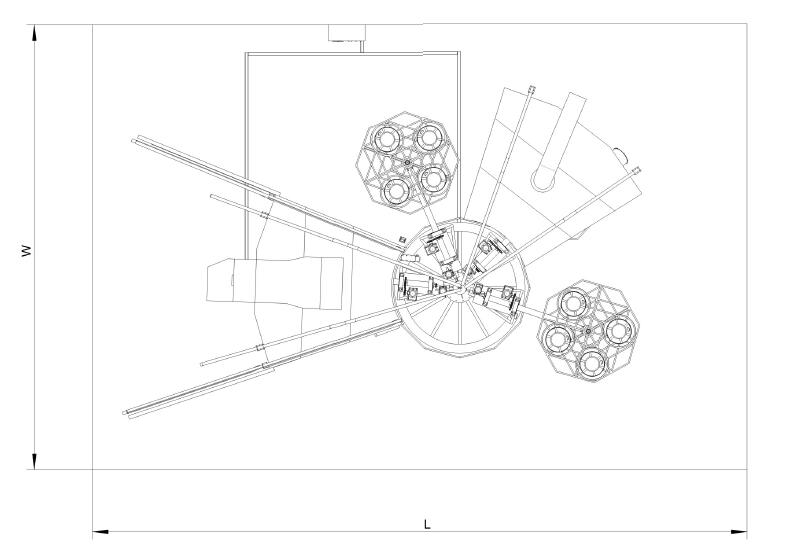

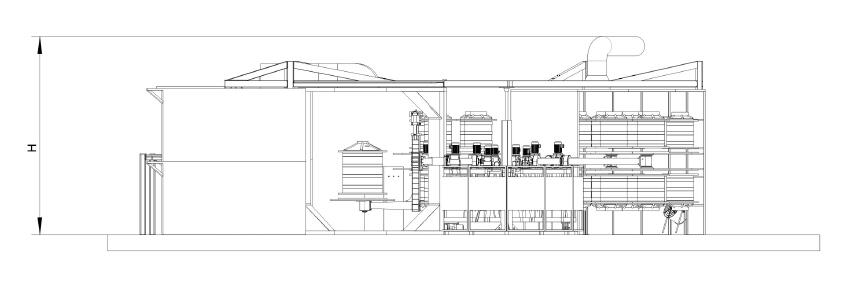

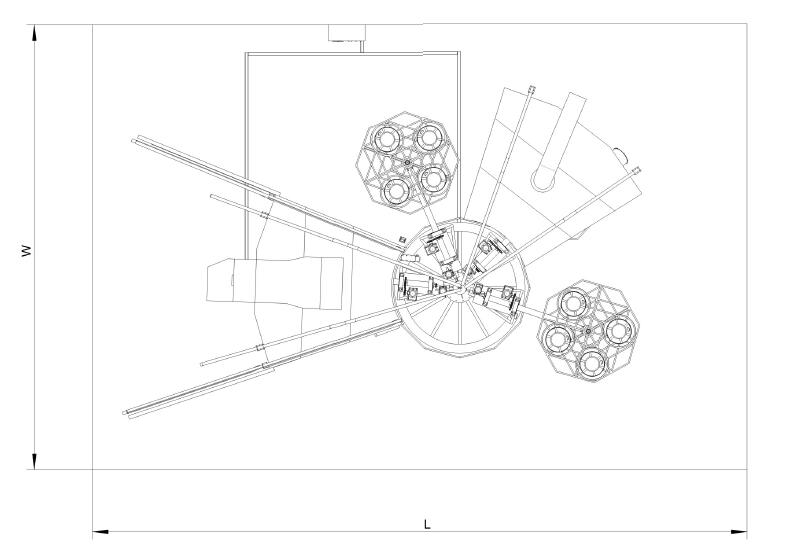

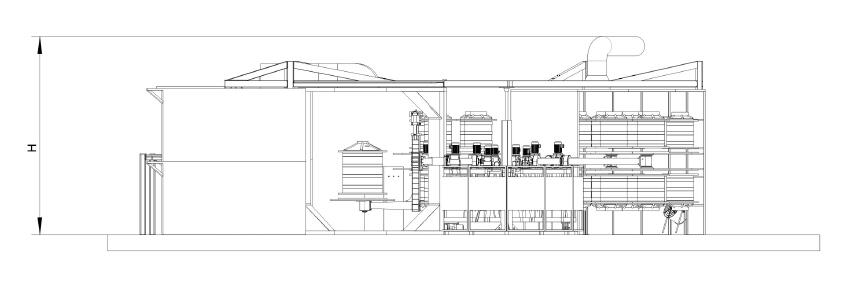

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Welcome to enquiry us! Rotate your business,Snowball your wealth!

.

Mold: Rotomolding machines employ molds, typically made of aluminum or steel, to define the shape and dimensions of the final product. These molds are hollow and can be single-piece or multi-piece, depending on the complexity of the desired part.

Oven: The oven is a crucial component of the rotomolding machine responsible for heating the mold and the polymer resin inside it. The oven's temperature and heating profile are carefully controlled to ensure uniform melting and distribution of the resin.

Rotating Mechanism: Rotomolding machines feature a rotational mechanism that rotates the mold along multiple axes simultaneously. This rotation ensures that the molten resin coats the inner surfaces of the mold evenly, forming a seamless, hollow part.

Cooling System: After the rotational molding process is complete, the mold is cooled to solidify the plastic part. Rotomolding machines are equipped with cooling systems, such as fans or water sprays, to expedite the cooling process and optimize cycle times.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Welcome to enquiry us! Rotate your business,Snowball your wealth!